Mills

The mills are suitable for making whole wheat flour and can be used for any dry grain milling as well.

Video how the machine works:

https://www.youtube.com/watch?v=-gOkMXIZlMU

https://www.youtube.com/watch?v=N4581t8i7Qs

The recommended moisture content of the grain that we want to grind should be maximum 7-12 % . The mills are equipped with cast self-sharpening mill stones

( stone mill pairs).

These stones are suitable for making flour from the desired dry grain in one step .

The smallest achievable grain size of the milled material is 60-80 microns ( 0.06 to 0.08 mm).

The fineness is shown by the fact that the fineness of wheat flour used today varies from 115 to 250 microns ( 0.115 to 0.250 mm).

By achieving such a fineness of the grist as a result of grinding, the mill is suitable for production of vitamins and dietary supplements such as preparation of grape seed , dried fruit , dried herbs, dried tea plant grist.

Here I highlight that our stone mill is the best machine for high -quality paprika production.

Beside producing a fine ground paprika,the stone mill makes the obtained grist even redder with the help of the oil in the pepper.

For performing the above listed tasks the millstones have a food industry qualification( millstone)

.

Stone mills were already used in the 10th- 13th centuries for making grist and flour .

Our stone mills also use these old proven methods, combining them with the advantages of modern technology.

So the mills meet the required standards of modern food industry and today 's expectations,

such as:

- The millstones have a food industry qulification ;

- Metal parts in the mill , which grind the desired material , and come into contact with the flour are made of stainless steel (inox) ;

- The wooden parts of the mill are made of qualitative steamed beech ;

- We`ve kept the rev of the millstones low (like in windmills or watermills in the past) ;

- With the low rev of the millstones we perform a so-called cold milling ;

-During cold milling the obtained flour doesn`t lose its valuable components ;

- We prepare fine whole wheat flour in one working session ;

- The consumption of whole wheat flour is healthy ;

- Fast change over between grist qualities ( flour , semolina , grits ) ;

- It can be set in production line, and can be automated

- Simple mechanical solutions , easy use.

What we grind:

Wheat, Bankut wheat, spelled wheat, rye, flaxseed, millet, soybeans, corn, buckwheat, rice, grape seed, peanut, pumpkin seeds, almonds, hazelnuts, pepper, cumin seeds, caraway, anise, black pepper, dried herbs, oats, barley, dried fruit, coffee, peppers, hemp seeds, zeolite, cherry pit, apricot seeds, hazelnut shell, nutshell, poppy , nuts, moisture content up to 7-12%, sugar, cinnamon, roasted soya

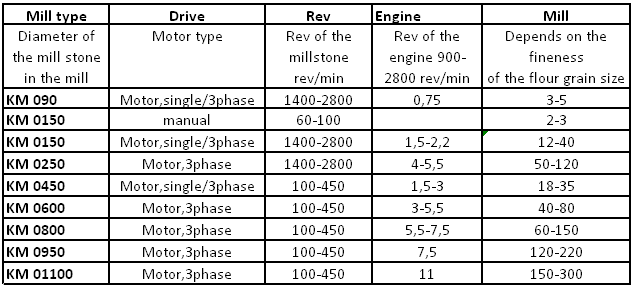

Type / Prices

KM Ø90 = 550 Eur

KM Ø100 kézi =280-300 Eur

KM Ø125 = 650-850 Eur

KM Ø150 = 750-2600 Eur

KM Ø250 = 3200-4200 Eur

KMR Ø450 = 2400-3800 Eur

KMR Ø600 = 3700-5500 Eur

KMR Ø800 = 5500-7500 Eur

KMR Ø950 = 7800-9800 Eur

KMR Ø1100 = 12500-16000 Eur

Video how the milling machine fi90-fi150 works: